SHW PERFORMANCE

As a Distributor for SHW Performance, we offer fast shipping and local support of all their products. Due to so many products being available please contact us to check available SHW products for your car. There are constantly new products and an expanding range.

SHW Performance- The Only True Replacement.

NOTHING LESS THAN A TRUE FACTORY EQUIVALENT

Unparalleled Cooling Advantages

As well as a reduction in unsprung weight and improved braking characteristics, SHW’s Pin-Drive design also prides itself on offering unbeatable cooling advantages, just one of the reasons why it has become the first choice for many OEM’s.

Unlike other brake manufacturers, SHW developed a PATENTED improvement of the disc construction by offsetting the pin connection of the friction ring to the aluminium disc bell away from the center to the edge, which results in huge cooling gains.

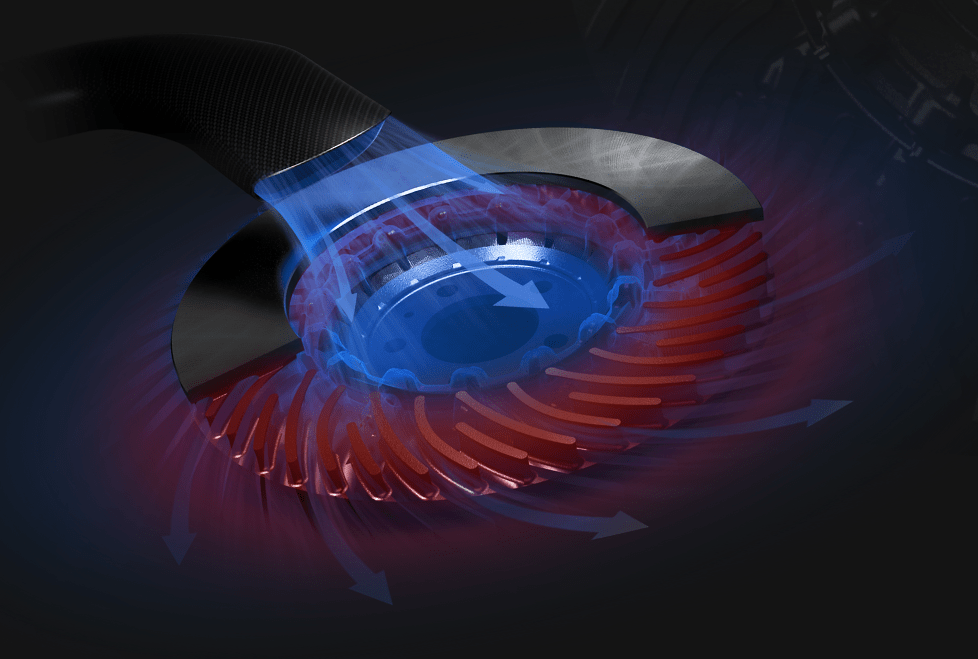

By offsetting the pin connection of the friction ring to the aluminium bell the cooling channels running centrally through the rotor see a huge increase in accessibility and cooler air flow. This advantageous design offers up to a 50% cooling advantage gain when compared to traditional designs.

Allowing a greater flow of air, heat generated on the surface of the friction ring (via the brake pads clamping down under braking) is carried away faster and more efficiently, dramatically reducing inner core and surface temperatures across the complete disc brake rotor. In addition, due to the unique patented design, further weight savings are achieved thanks to a shallow aluminium disc bell.

Patented Design Pin-Drive System

Innovation, sustainability, added value. Welcome to SHW’s patented Pin-Drive system, a substantial step forward in the future of braking.

SHW’s Pin-Drive system carries many benefits when compared to conventional methods of disc brake rotor design. So, what is ‘Pin-Drive’ and why is it advantageous over a one-piece disc brake rotor?

The Pin-Drive system is a two piece fully floating disc brake rotor. The friction ring is connected to the central aluminium rotor bell by means of stainless steel pins which are cast into the assembly during the manufacturing process. The purpose behind the design is to offer a range of advantages:

– Up to 5.5lbs of weight reduction (rotating and unsprung weight) per disc compared to Monoblock.

– Reduced thermal strain thanks to the friction ring having more freedom to expand and contract.

– Low brake fading properties.

– Improved durability.

– Enhanced brake comfort thanks to optimised thermal conditions.

– Optimal curved vane design that maintains structural strength while improving noise dampening.

The Importance of Airflow

The right diagram highlights the path of cold air entering the rear of the brake disc rotor assembly. The cold air is traditionally fed via air ducts located either in the front bumper, or channeled through pathways on the underside of the vehicles under tray.

As the cold air enters the rear of the disc bell, it passes through vanes between the two brake rotor faces. The cooler air helps to reduce temperatures from the very core of the brake disc by collecting heat and carrying it outwards, away from the brake disc assembly and eventually venting back out into the passing air flow found circulating the inner wheel

With the RS3 there is no park assist offered so the switch is blank. The replacement multi switch uses the park assist switch to operate the valve motors with LED feedback. This offers ease of use and no fumbling for that remote when a quick valve change is required, it is also a subtle way of switching where a louder exhaust system or downpipe is used using an original part making the whole system look totally stock.